Polyethylene sheeting under concrete slab.

Polythene sheet for concrete.

Polythene sheet roadway expansion projects must fill a number of requirements to minimise environmental impact.

Starting with lower water cement ratio concrete will let the slab dry faster.

Typical 8 mil polyethylene sheeting costs 5 to 7 cents per square foot.

The general standard employed for the testing and verification of polythene sheets for use as a vapor barrier is the astm4397.

It is recommended that the sheet should be at least 0 25 mm thick 1200 gauge.

Keep w c at or below 0 5.

Vapor barriers also block gases such as methane or radon.

These products are made.

Polythene sheet we are the leading manufacturer of ldpe sheet for construction and our product is made of good quality.

Roadways must be properly and effectively protected for safety and long term reliability concrete.

Under slab vapor retarders play a very important role in retarding moisture from coming up through the concrete and into the structure.

Today most experts feel very strongly that engineered films designed specifically for use as vapor retarders should be used as vapor retarders.

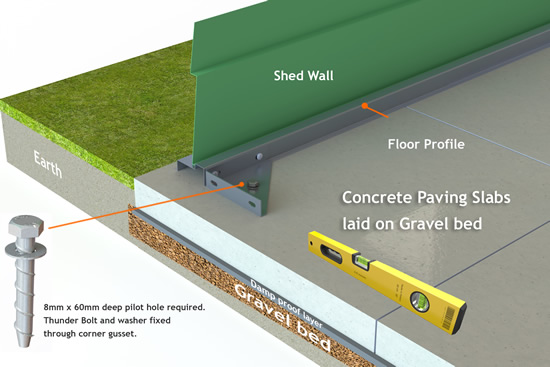

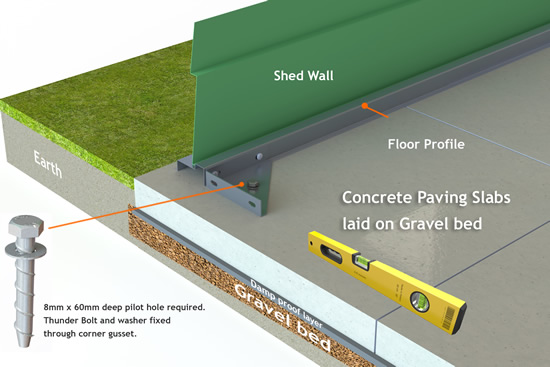

Oversite concrete slabs employ a 1000 guage 250 microns polythene sheet laid underneath the concrete to prevent the moisture from being absorbed.

A concrete vapor barrier is simply a sheet of polyethylene plastic visqueen placed directly on top of the sub grade before the concrete floor or slab is poured to help keep moisture from the soil from passing up through the concrete.