Then use your bend allowance to draw your second bend line the intervening distance between your bend lines bend radius.

Putting a bend on a curve sheet steel.

For 3mm i use a big piece of angle iron.

If in doubt try bending a scrap panel over the tightest radius section of the arch to see if it will work.

Clamp the box section on top of the shims feed the metal through and pull up then feed the metal through a few mm at a time gentle tweaks using the long side when you reach the middle turn it round and repeat.

A cutout or the edge of your flange to your bend.

To clamp efficiently lay your sheet metal on the top surface of your straightedge with the drawn line perfectly aligned with the outside edge of the sheet metal.

The last step bending will actually deform the first bend and make that bend less then 90 degrees so for that to look good.

It seems like it should be simple but i think the flat part where the tab originated is making it difficult.

Clamping your sheet metal to the straightedge is a must.

If you have any questions or want to discuss your design contact us.

Choose a bend radius that matches your minimum bend.

Finally curved applications typically require additional fasteners to resist the forces induced by curving the panels.

The sheet metal is bent to follow the pipe s contours using mallets.

Note watch out for overbending the workpiece.

This is putting a simple hem on a curved piece of zinc with a 7ft radius.

Make sure the first bend mark lines up exactly with the curve in the form so that the bending will begin in the right spot.

Using protective gloves hold the free end of the metal sheet with one hand and with the other hand use a mallet or hammer to begin bending the sheet down and around the curved radius of the wood form.

Curve sizes vary depending on the pipe diameter utilized.

Mark your bend lines.

Otherwise the sheet metal is almost certain to shift as you bend it resulting in a bad bend.

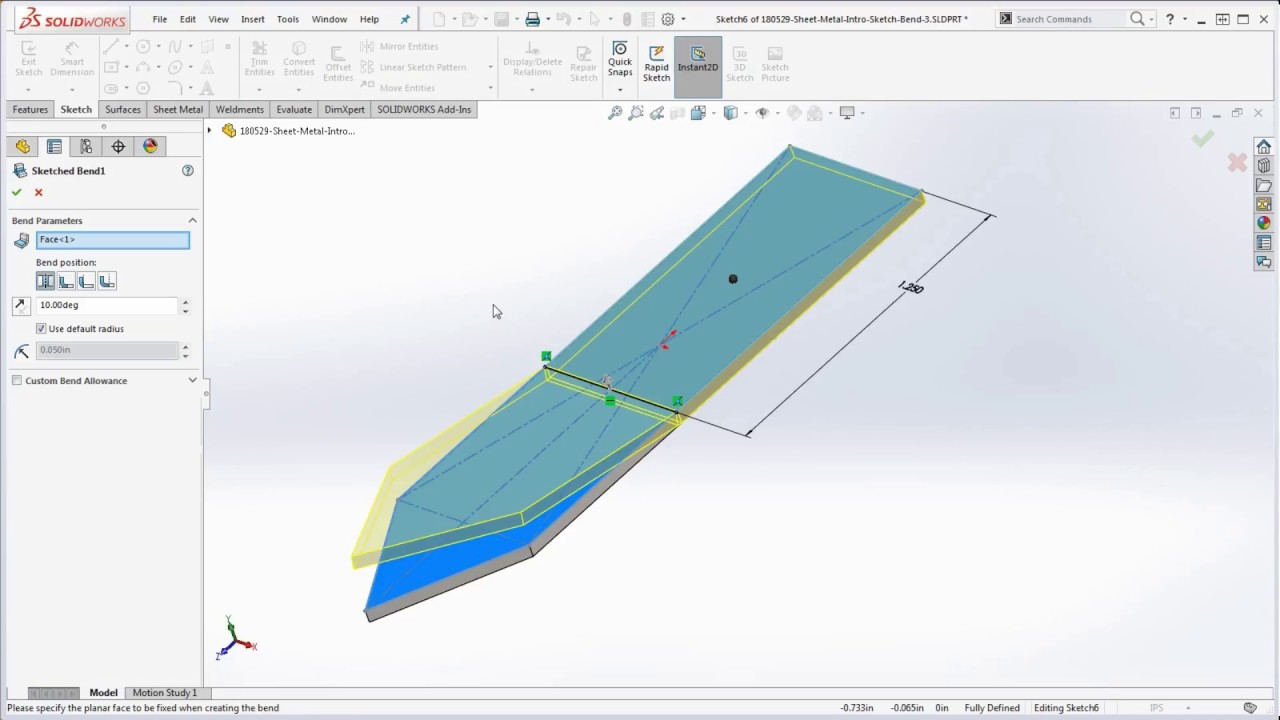

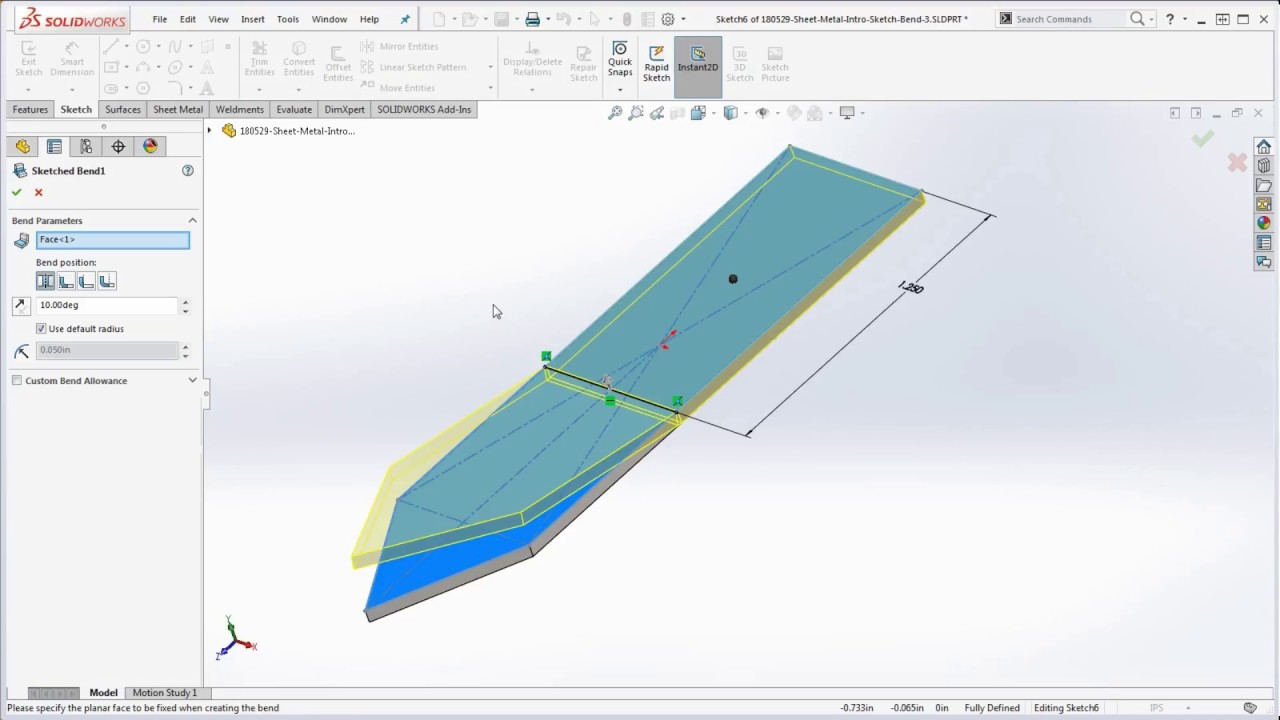

I am trying to put a curve on a bent tab in a sheet metal part and i can t figure out how to make it work.

Now that you know your bend allowance take your protractor and draw a clear line with your marker across the point at which you will bend your sheet metal.